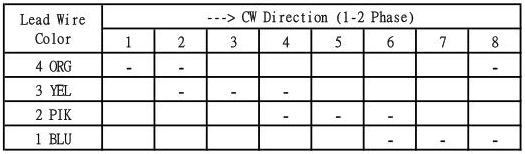

Motor Typeĥ Wire Connection (to the motor controller) Here are the detailed specs of the 28BYJ-48 stepper motor. Quite a bargain, compared to the price of a geared DC motor, a DC motor controller and a wheel encoder! The low cost and small size makes the 28BYJ-48 an ideal option for small robotic applications, and an excellent introduction to stepper motor control with Arduino. These little steppers can be purchased together with a small breakout board for the Arduino compatible ULN2003 stepper motor driver for less than $5. With some software “trickery” to accelerate gradually and a higher voltage power source (I tested them with 12 volts DC) I was able to get about 25+ RPM. Due to the gear reduction ratio of *approximately* 64:1 it offers decent torque for its size at speeds of about 15 rotations per minute (RPM). The 28BYJ-48 is a small, cheap, 5 volt geared stepping motors. These stepping motors are apparently widely used to control things like automated blinds, A/C units and are mass produced. The downside of using steppers is that they are a bit more complex to control than servos and DC motors. The advantage of steppers over DC motors is that you can achieve much higher precision and control over the movement.

Servos though, are usually limited to a 0-180 degree range, while a stepper motor can rotate continuously, similar to a regular DC motor. For practical purposes, a stepper motor is a bit like a servo: you can tell it to move to a pre-defined position and can count on getting fairly consistent results with multiple repetitions.

One thing that you cannot tell from the video is how quiet these little steppers run: StepperBot is very stealthy! Eventually, small errors add up over time and the bot falls off the table, but it typically runs for 10-15 minutes, before that: good enough for me! What is so special about steppersĪ stepper motor can move in accurate, fixed angle increments known as steps. The motors are running at approximately 8 volts DC and 15 RPM in this example. Movement is controlled only by the number of pre-defined steps in each direction hard-coded in the sketch. The robot has no sensors for positioning, orientation, or a way to detect the edges of the table. Turning exactly at the right time and by the right angle is critical avoid falling off and crashing on the floor in an embarrassing pile of messy wires.

First, lets see the little steppers in action! Our main character, StepperBot, is “instructed” to move in a square path on my coffee table, making 90 degree turns at the corners.

0 kommentar(er)

0 kommentar(er)